|

|

|

|

Tai Hei Shakuhachi is the originator of the Precision Cast Bore technology nearly a decade ago. This method of construction has revolutionized flute making process and craftsmen around the world, including Japan, have attempted to copy this special technique with mixed results. Most of these makers use simple forms for casting or hire industrial machine shops to produced lathe turned mandrels. Tai Hei Shakuhachi not only makes all of its master forms, but has helped to invent and build the device with produces these precision mandrels. An innovative laser tracker, co-developed by Monty Levenson and Baroque flute maker Rod Cameron, (only two in the world exist) guides cutting of the forms at incredibly high resolution comparable only to an expensive computer driven lathe.

Research and development is an important part of the flute making process. Mandrels are continually updated and improved to take advantage of the data derived from studies in woodwind acoustics and insights into the physics of the shakuhachi bore that have come out of my direct experience.

I recently trained a maker of traditional shakuhachi in Japan, who has been making instruments for over 25 years, in the precision cast bore process. Tai Hei Shakuhachi are now being made in collaboration with this maker, along with John Kaizan Neptune, one of the most highly-regarded players of the instrument, to produce flutes being used by professional musicians and traditional teachers all over Japan.

The initial aim of the precision cast bore technology had been to provide decent sounding, finely tuned instruments at an affordable price for folks who were interested in starting out on the shakuhachi. The spiraling cost of imported flutes during the 1970's and '80's, along with their propensity to split in the diverse climates of North America, discouraged music stores from stocking shakuhachi and people from trying them out. For many years, the standard for beginning students of the traditional music had been a simulated lathe-turned wooden shakuhachi made with an unrefined bore. The first cast bore shakuhachi were made during the Winter of 1987. Little did I know that within a few years these instruments would not only replace the wooden variety, but be chosen by traditional teachers and professional shakuhachi players around the world as their own personal instruments. Within a short period of time, Tai Hei Shakuhachi emerged as an alternative that was both higher in quality and lower in price than instruments imported from Japan.

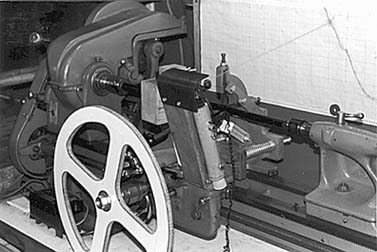

Electronic bore measurer invented by baroque flutemaer Rod Cameron, provides parameters of the flute accurate to .01mm. A computer interface for this device was developed by Rod, Monty and Darrel Dean.

At the heart of this development is

the precision cast bore© technique which has the ability

to reproduce -- with near perfection -- the bore dimensions of

historical flutes and modern instruments of the finest quality.

Access to these shakuhachi have been provided to me by some of

the leading makers, teachers and players in Japan today. The interior

of these "gauge" flutes are very carefully measured

and analyzed in an intricate process which renders the profile

of the bore into an enlarged graphic format. A finished graph

charts the bore in two stages -- initially at 25 times, then to

over 50 times its actual size -- and can be clearly read

to within .01 mm (.0025"). This degree of accuracy is critical

as subtle variations in the bore of the flute can make a dramatic

difference in the instrument's resonance and tonal quality. Working

from a "gauge" flute is similar in approach to the way

that traditional makers in Japan create their instruments. Tai

Hei Shakuhachi's precision casting method, however, significantly

reduces the time it takes to fabricate the interior of the flute.

More importantly, it provides a degree of precision and repeatability

impossible to achieve in traditional attempts at duplication.

These differences are ultimately reflected in performance as well

as in the price of the finished product. Extreme accuracy in bore

duplication enables Tai Hei Shakuhachi to improve continually

over time as enhancements in bore design are maintained through

successive generations of instruments produced. The process of

refinement is cumulative.

Measurement, casting and techniques of reproduction are just part

of the process involved in making a well-playing shakuhachi. Quality

instruments cannot be mass-produced as the shakuhachi, by its

nature, defies standardization. Since each piece of bamboo is

unique -- differing from the "gauge" flute in size,

shape and diameter -- very fine adjustments must be made in the

bore to establish balance and resonant frequencies for each of

the notes. Building upon the work of John Kaizan Neptune, a leading

player, composer and flutemaker in Japan who has engaged in a

pioneering effort to map the acoustical parameters of the shakuhachi,

I am working toward developing a better understanding of how minuscule

changes in bore profile affect timbre, balance and subtle harmonic

variations in the sound produced by this instrument.